American Farriers Journal

American Farriers Journal is the “hands-on” magazine for professional farriers, equine veterinarians and horse care product and service buyers.

Borium is a hard-facing rod that we weld to horseshoes to extend wear and/or adds traction, depending on how it is used. Borium is applied to the shoe with a torch using a technique called brazing. The rod contains carbide particles in various sizes depending on what size rod one uses.

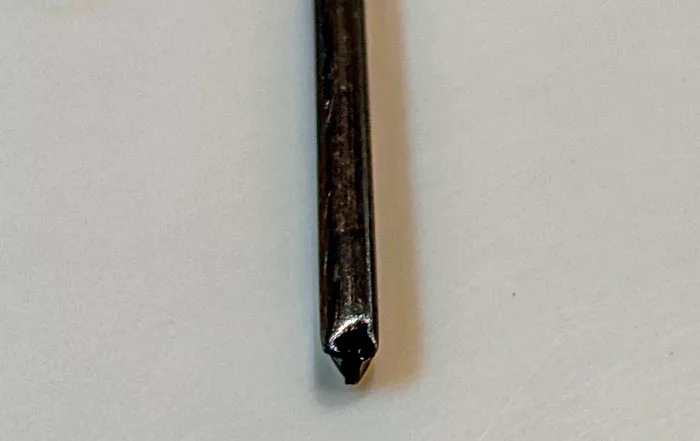

I specialize with Standardbreds. The normal rod we use for Standardbred racing is 1/8-inch and contains carbide crystals slightly larger than table salt (Figure 1). Larger ¼-inch rods have crystals slightly larger than kosher salt and is usually considered too coarse for racehorses. When these rods are melted by an oxyacetylene torch with the correct application of heat relative to the rod, that rod casing will melt and adhere the carbide crystals to the horseshoe. The carbide is much more wear resistant than steel itself. It will help to maintain a horseshoe profile for significantly longer than that shoe would last without it.

Applying borium to aluminum shoes is not usually done. In fact, it cannot be welded directly to aluminum. These shoes usually have a hardened steel traction or wear plate built in during the manufacturing process. It is possible to enhance the grab of aluminum shoes, but is mostly unnecessary given the number of shoes available with a variety of traction effects. If needed, borium nails can be used in the aluminum shoe for augmented traction.