American Farriers Journal

American Farriers Journal is the “hands-on” magazine for professional farriers, equine veterinarians and horse care product and service buyers.

Every business must limit its expenses. It is even more critical during the uncertain financial times of today. Along with this, a business owner wants the most effective and efficient uses of the tools he or she uses. If you as a farrier aren’t taking steps to extend the lives of your hand tools or keep them working at optimum levels, you’re costing yourself money in wasted resources and unrecognized efficiency.

First, accept the fact that your tools are going to breakdown. Hall of Fame shoer Bob Schantz of Spanish Lake Blacksmith Shop in Foristell, Mo., will joke that the only way to preserve your tools is to not use them.

Dan Bradley of G.E. Forge and Tool says it is easy to ignore tool wear over a 3-year period.

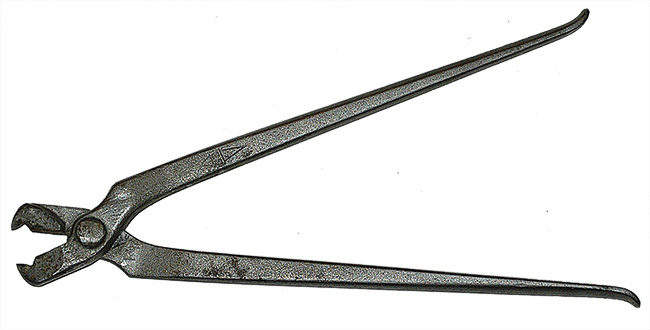

“Over this time, wear is taking place and the handles will get closer together,” says the Lucedale, Miss., shoer. He believes most farriers don’t notice this gradual process until it is too late — invariably on a cold day — and pinch a finger between the handles.

It is usually at that point that the farrier realizes it is time to do something. If you don’t want to wait until the agony of a pinched finger, Bradley suggests the best way to monitor a tool’s health is by gauging the looseness of its rivet.

Bradley believes most shoers wait a little long in the tools’ lives to get their tools refurbished.

“Being human, that is a natural…