American Farriers Journal

American Farriers Journal is the “hands-on” magazine for professional farriers, equine veterinarians and horse care product and service buyers.

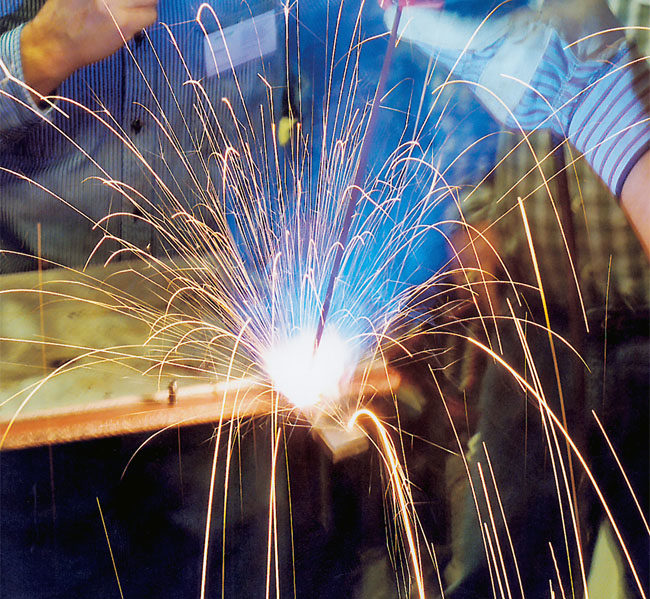

Why should a farrier choose to arc weld rather than use a gas welder?

Arc welding offers three advantages over forge or gas welding your shoes.

When it comes to welding shoes and clips, you need to follow some basic steps to get your shoe modification work done right.

I carry several pairs of bars in my truck that are made up ahead of time. To make the bars, start with steel that has about the same dimension as a steel shoe.

Since I use mostly Kerckhaert SX 7 and 8 shoes, I use 1/4-by-3/4-inch or 5/16-by-3/4-inch bar stock. For size 0 or smaller shoes, I’ll start with a 4-inch long piece of steel. For size 1 or larger shoes, use a piece of steel that’s 5 inches long.

After cutting the steel to length on a carbide cutoff saw, notch the center of the bar 5/16 inch deep. Don’t cut too deep or you’ll weaken the bar. Then heat the bar in a forge and make a 40 degree bend in it so you can open or close the shoe on resets.

To apply the bar shoe, first shape the shoe to the hoof. Then place the bar under the shoe from heel to heel (Figure 1). Mark the bar with soap stone inside the heels and cut it with an oxyacetylene torch. Place the…