American Farriers Journal

American Farriers Journal is the “hands-on” magazine for professional farriers, equine veterinarians and horse care product and service buyers.

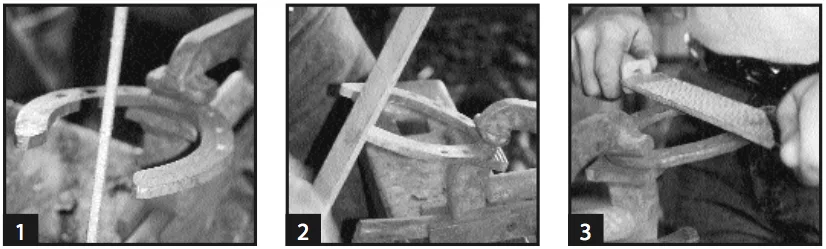

Building good shoes is only part of the skills needed to compete and pass certification tests. Presentation of the finished product is also important.

For my everyday shoeing, I rarely rasp the shoes. Most of what I need to do is done with the hammer. The horse doesn’t care if the surface is shiny and most of my customers look through the fluff anyway. However, if you are building specimen shoes for contests, certification or for a personal display, you want them to look as pretty as possible. Finishing the shoes, as well as the hooves, can also be important for your clients who are entering their horses in shows.

You should work toward a good finish throughout the forging process. While you can give the shoe a good finish after it is built, periodic brushing while you are still forging will make finishing the shoe at the end easier. Anytime you are doing a forging process that does not move a lot of steel, brushing becomes even more essential. The reason is that the scale (the surface on the steel oxidized by heating) will be broken off if there is a lot of movement of the steel. A toe bend will become fairly clean without brushing because of the amount of movement, while a clipping heat can really ruin the finish.

Another reason to brush during the forging process is to remove anything from the hot steel that can be driven into the surface. Scale and…